Main features:

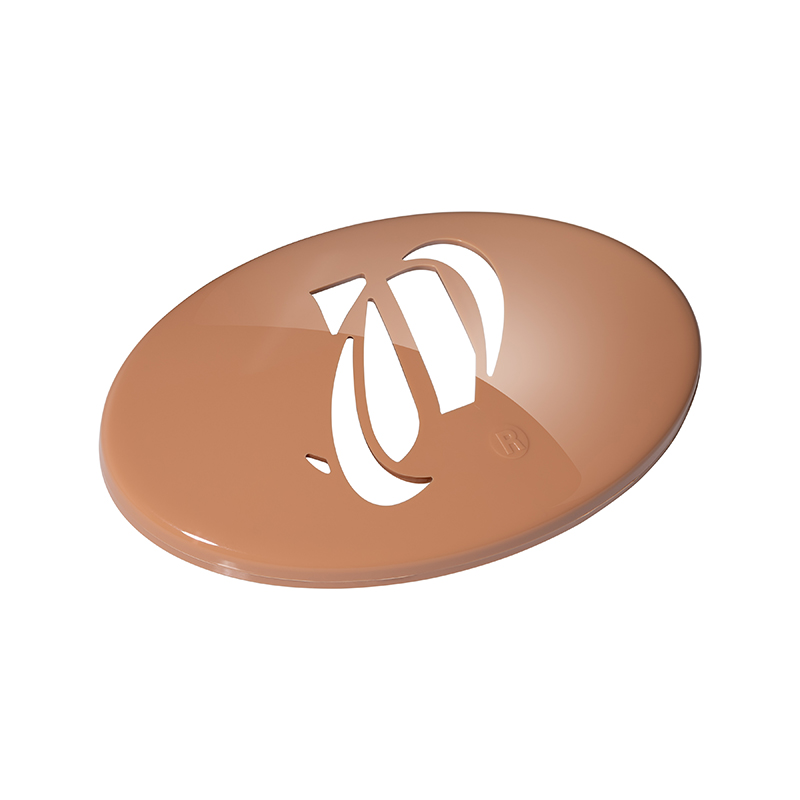

One kind of custom-machined tool used in plastic injection molding to shape molten plastic into plastic parts.

Summary:

Plastic Injection Molds for Plastic Parts shaping made by resins of PP,PC,PA,PA6,ABS,PET,PVC,POM,.etc

An plastic injection mold is one of the custom-machined tools used in plastic injection molding to shape molten resins into plastic parts.

Manufacturers design these molds for specific plastic products they want to produce. JDmoulding offer customers common 2 plates injection molds or 3 plates injection molds.

Parameter:

FAQ

1. Q :Do you have experience to build export mould?

A:Yes, we do. 95% are exported molds. moulds are made according to customer requirements and plastic parts are made and export directly from our factory also.

2. Q :How many moulds could you make every month?

A:15-30 sets.

3. Q :How many employees do you have?

A:30

4. Q :How about the largest mould you can make?

A:8 ton. The size is 1.5m x 1.0 m.

5. Q :Can you make precision mould ?

A:Yes. And we can hold mould tolerance +/- 0.005mm, product tolerance +/- 0.01mm.

6. Q :How about the steel you usually use?

A:We only use steels such as P20, P20H, 718H, NAK80,1.2311,1.2378, 1.2344, 1.2343 ESR, 1.2767, H13,8407, 420SS, S136, S-7,etc.

7. Q :What is the standard of your hot-runner system?

A:It’s decided by the customers. We have famous hot runner suppliers locally, such as MOLD

MASTER,INCOE, YUDO, DME, SYNVENTIVE, HUSKY, HASCO,EWIKON, GUENTHER, etc.

8. Q :What kind of standard components do you use?

A:HASCO, DME, PROGRESSIVE, STAUBLI, RABOURDIN are available.

9. Q :What do you need for quotation? And what about the software?

A:2D & 3D part files and mold specifications are preferred.

We mainly use UG and AUTOCAD. But it is OK for us to read the files of Solidworks, PRO-E etc.

10. Q :What is your turnround time for injection mould building?

A:Usually 4 to 10 weeks. It also depends on mould size and structure complexity.