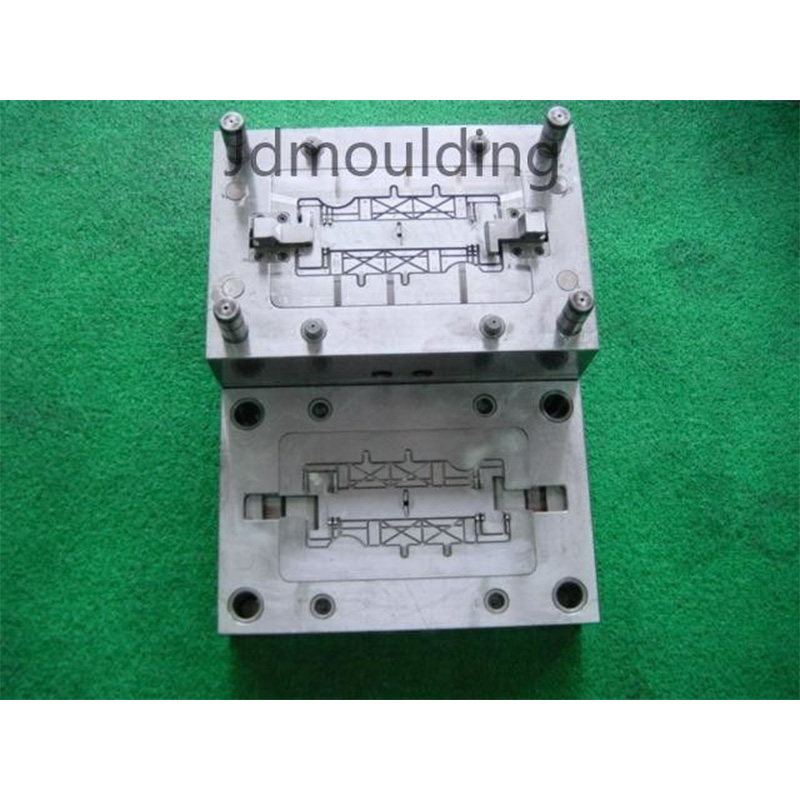

Hot Runner NAK80 Custom Plastic Injection Molding LP 2 Texturing

Hot Runner NAK80 Custom Plastic Injection Molding LP 2 Texturing

High Light:NAK80 Custom Plastic Injection Molding, HASCO Plastic Injection Molding, DME Hot Runner Molding

Mould Material:NAK80

Cavity:1*1

Shaping Mode:Plastic Injection Mould

Surface Finishing:Texture

Runner:Hot Runner

Standard:DME,HASCO

Place of Origin:Shenzhen , China

Brand Name:OEM

Certification:ISO 9001 : 2015 , CE

Model Number:Cusomized

Minimum Order Quantity:1 set

Price:Negotiate

Packaging Details:Mold : packed by wood carton

Delivery Time:30 Working Days T1

Payment Terms:T/T, L/C, D/A, D/P

Supply Ability:30 sets Per Month

FAQ

1.Q:Do you have experience to build export mould?

A:Yes, we do. Over 95% of our molds are exported.

2.Q:How many moulds could you make every month?

A:30-35 sets.

3.Q:How many employees do you have?

A:90

4.Q:How about the largest mould you can make?

A:8 ton. The size is 1.5m x 1.0 m.

5.Q:Can you make precision mould ?

A:Yes. And we can hold mould tolerance +/- 0.005mm, product tolerance +/- 0.01mm.

6.Q:How about the steel you usually use?

A:We only use raw materials with good quality like P20, P20H, 718H, NAK80,1.2311,1.2378, 1.2344, 1.2343 ESR, 1.2767, H13,8407, 420SS, S136, S-7,etc. They are all from famous suppliers, such as LKM,ASSAB, THYSSEN, etc. Steel certificate and heat-treatment certificate will be provided along with the tools ,while delivery if required.

7.Q :What is the standard of your hot-runner system?

A:It’s decided by the customers. We have famous hot runner suppliers locally, such as MOLD MASTER,INCOE, YUDO, DME, SYNVENTIVE, HUSKY, HASCO,EWIKON, GUENTHER, etc.

8.Q:What kind of standard components do you use?

A:HASCO, DME, PROGRESSIVE, STAUBLI, RABOURDIN are available.

9.Q:What do you need for quotation? And what about the software?

A:2D & 3D part files and mold specifications are preferred.

We mainly use UG and AUTOCAD. But it is OK for us to read the files of Solidworks, PRO-E etc.

10.Q:What is your turnround time for injection mould building?

A:Usually 4 to 10 weeks. It also depends on mould size and structure complexity.

Product Description: | LP-2 injection mold |

Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

QC: | Latest precise detecting instruments Well trained and skillful inspectors.Timely feedback to manufacturing department High yield rate and timely delivery. |

Feature: | Non marking and Non flash |

Size: | According to your 2D, 3D Drawing |

Color,Quantity,Unit price,Tooling cost,Tooling size: | To be discussed |

Package: | Standard exported Wooden box packed, Fumigation process(upon required) |

Mold Building Lead Time: | T1, 4-5 weeks, Part measurement report (upon required). |

To be discussed | Injection Mould, Plastic Mold, Overmould, 2K Mould, Cold Runner/Hot Runner ...etc. |

Mould Base: | Hasco Standard, European Standard, World Standard |

Mould Base Material: | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

Surface Finish: | Texture(MT standard), High gloss polishing |

Cavity/Core Material: | P20, H13, 2344, Starvax 420, 1.2343/1.2311/SKD61,S136,NAK80,H13,738H,...etc. |

Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

Mould Life: | 500,000 to 1,000,000 Shots. (According to your working environment.) |

Equipments: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |