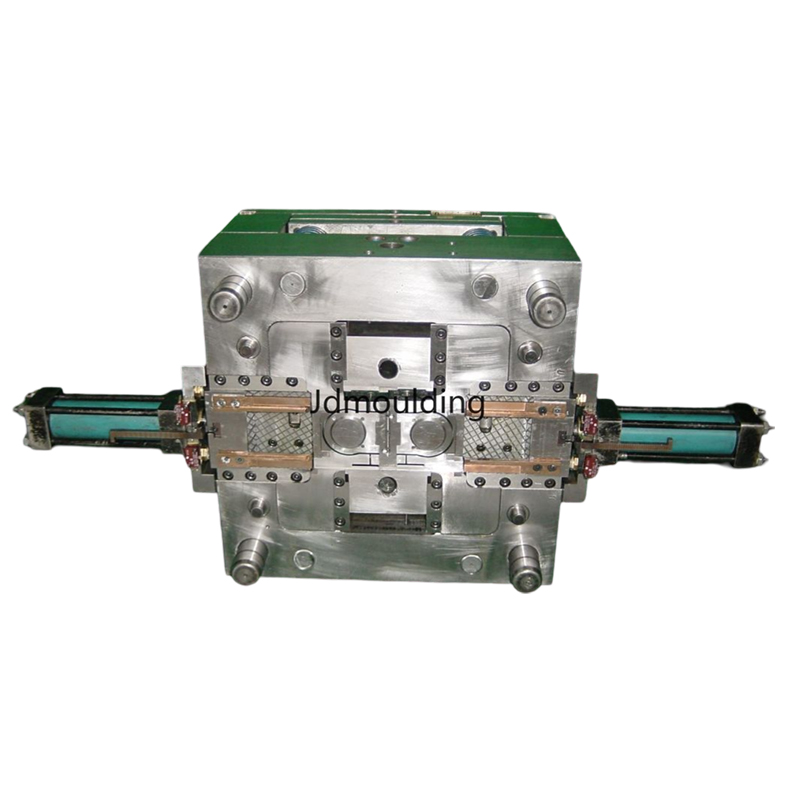

High Light:HASCO Auto Parts Mould, 1.2324 Auto Parts Mould, S136 Auto Parts MoldingMould Material:S136 1.2324Cavity:1*1Shaping Mode:Plastic Injection MouldSurface Finishing:PolishSize:Customized SizeStandard:HASCOPlace of Origin:Shenzhen , ChinaBrand Name:OEMCertification:ISO 9001 : 2015 , CEModel Number:CusomizedMinimum Order Quantity:1 setPrice:NegotiatePackaging Details:Mold : packed by wood cartonDelivery Time:30 Working Days 1 T1Payment Terms:T/T, L/C, D/A, D/PSupply Ability:30 sets Per Month

FAQ

Q1 How long do you evaluate the price after you receive the RFQ?

Normal we provide the quotation to the customer in three working days; if the project is very urgently, then we will try our best to provide it within one day.

Q2 What kind of requirements do you need when making a quotation?

For mould manufacturing

1)2D/3D Part Drawing, Mold Drawing;

2)Cav. No., Type of Hot runner and No., Type of mould steel, standard(ie.DME, Hasco etc),

3)Plastic material in uses, any special design enquired from customer For production (in house mould) Annual production amount,

4)Plastic material details; Part and runner weight (if available); Inspection requirements.

For production (mould transfer from customer)

2D part drawing with detail dimension shown, Mould drawing, Plastic material details, Part and runner weight, Mould age, Cycle time, Samples, Inspection requirement, and other special requirements.

Q3 Do you have on-site English-speaking engineers and Marketing person?

Yes, we do. Our project engineers and marketing person all can speak English well. They use English to send the e-mail to our customer for daily engineering communication.

Q4 What the min precision (tolerance) can you make?

The precision can be 0.05mm.

Q5 What type of formats do your mold drawings use often?

We often use .dwg, .step, .prt and .igs catia also.

Q6 What kind of hot-runner do you use?

Usually we use Mold-Master, Incoe, Yudo, Hasco, D.M.E., Husky and Synventive so on.

Q7 What kind of steel do you use? What’s the type?

We can use all types of steel appointed by customer. Usually we use LKM, Swiss Assab steel. The major types: P-20, HHP-20,S420,H-13, S136, NAK80,1.1730,1.2738,1.2312,1.2344

Q8 What's the payment term?

Generally payment term accepted by chinese mold factories are 40 with PO,30 with T1 sample submit,30% before mold shipping, For prototype mold/moulding, pay 50% when place P.O. and another 50% before mold/parts delivery.

Q9 How long it will take to make the mold?

Depends on the mold size complexity,small size/easy structure molds take.